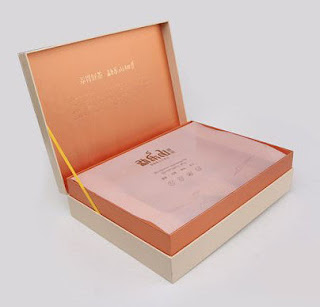

Red wine sales are roughly driven by three factors, brand effect, promotional efforts and packaging. An excellent gift packaging box is undoubtedly a free walking advertisement.

Thursday, August 8, 2019

Make your red wine brand stand out from the rest

How can your red wine brand stand out from the rest? Surely, it takes a integrated marketing strategy. But hereunder, we'd tap into this topic in terms of packaging, and take China market as an example. Red wine consumption has seen dramatic growth in China, in recent years, and brands have mushroomed accordingly. The packaging plays a significant role in the market competition.

Red wine sales are roughly driven by three factors, brand effect, promotional efforts and packaging. An excellent gift packaging box is undoubtedly a free walking advertisement.

When Chinese consumers buy red wine without knowledge of the tastes, they tend to make a subjective judgment on the taste and quality of the dazzling wine brands through the visually-perceptible packaging, somewhat like the halo effect. Hence, the first impression reigns, and the part that attractive packaging plays in the purchase decision process is beyond imagination. Therefore, personalized design of wine packaging is particularly important.

Red wine sales are roughly driven by three factors, brand effect, promotional efforts and packaging. An excellent gift packaging box is undoubtedly a free walking advertisement.

What gift boxes can make your products hot sale?

In this era of information, we are flooded with information of all types, while what we can consume is limited. Therefore, if you want to sell the products well, you should work hard on the packaging.

When designing the packaging, it is necessary to take into account all aspects of the customer's needs and product requirements.

1. Meet the aesthetic standards of the time, in line with specific local cultures and use attractive themes to catch the eyeballs of the masses.

2. Have a creative packaging design, which may be the most attractive and crucial. But it can't be too maverick, as creativity that derails from the era may backfire.

3. The packaging should be practical. Otherwise however good it may look, the creativity is no more than a short-lived fad. This kind of cardboard gift boxes packaging won't last., because it's packaging in the first place.

4. Nowadays, the packaging is not just a combination of patterns, words, colors and ribbons. Its boundaries should go beyond those. For example, a flower spike or an animal with a funny expression can be added to the box.

5. Last but least, the quality of the cardboard gift boxes. After all, if you can't do well in the packaging which is usually perceived as simple and easy, how could others to expect the product inside to be good!

What do you think?

When designing the packaging, it is necessary to take into account all aspects of the customer's needs and product requirements.

1. Meet the aesthetic standards of the time, in line with specific local cultures and use attractive themes to catch the eyeballs of the masses.

2. Have a creative packaging design, which may be the most attractive and crucial. But it can't be too maverick, as creativity that derails from the era may backfire.

3. The packaging should be practical. Otherwise however good it may look, the creativity is no more than a short-lived fad. This kind of cardboard gift boxes packaging won't last., because it's packaging in the first place.

4. Nowadays, the packaging is not just a combination of patterns, words, colors and ribbons. Its boundaries should go beyond those. For example, a flower spike or an animal with a funny expression can be added to the box.

5. Last but least, the quality of the cardboard gift boxes. After all, if you can't do well in the packaging which is usually perceived as simple and easy, how could others to expect the product inside to be good!

What do you think?

Wednesday, August 7, 2019

Does your packaging help to increase the mind share?

Every seller may wish that their packaging would catch the eyeballs of consumers and finally get them to pay for it...And this post may help to this end!

First of all, in the planning and design phase of the packaging boxes, we need to understand the positioning of brand products and target consumer groups. That will help us come up with the right ideas for appealing packaging.

Secondly, the recognizability of your packaging, that is, whether the packaging has its unique features. An excellent packaging should be well distinguished from other brands, having your own brand style. Ideally, consumers who see the product packaging would link it the very brand. This is very similar to being a person. Characters with characteristics are simply remembered by others. Just imagine, when shoppers are searching a certain type of products in front of a retail shelf, they would quickly scan the shelves and make their buying decision through a comprehensive evaluation of vision and senses evaluation on assorted products on shelf.

Thirdly, interactiveness of packaging. the uniqueness and heterogeneity of such packaging will impact on consumer choice to a greater extent. The packaging that customers pay attention to is not an image or a fancy, but whether the packaging can convey people's emotions, resonate with people, and reflect the level and lifestyle of the target group.

Finally, the packaging plan should match the characteristics of the product. This is actually the most basic point. Food packaging boxes should give people a sense of food rather looks like pharmaceutical. Or package men products similar to those for female.

------------------------

Innove is a leading custom cardboard gift boxes supplier from China, offering various fancy setup gift box packaging products and custom box designs service. The product lines include personalized odd shaped boxes, round boxes, square boxes, rectangular boxes, telescoping boxes, shoulder boxes, cardboard drawer boxes, collapsible gift boxes - for clothing packaging, hexagon explosion gift boxes, cardboard window boxes, nesting gift boxes sets -stacking, etc. We've been serving diversified industries like gourmet cookie gift boxes, flat desserts boxes, cardboard flower gift boxes, jewelry gift boxes, luxury apparel boxes, t-shirt packaging boxes with clear lids, etc.

First of all, in the planning and design phase of the packaging boxes, we need to understand the positioning of brand products and target consumer groups. That will help us come up with the right ideas for appealing packaging.

Secondly, the recognizability of your packaging, that is, whether the packaging has its unique features. An excellent packaging should be well distinguished from other brands, having your own brand style. Ideally, consumers who see the product packaging would link it the very brand. This is very similar to being a person. Characters with characteristics are simply remembered by others. Just imagine, when shoppers are searching a certain type of products in front of a retail shelf, they would quickly scan the shelves and make their buying decision through a comprehensive evaluation of vision and senses evaluation on assorted products on shelf.

Thirdly, interactiveness of packaging. the uniqueness and heterogeneity of such packaging will impact on consumer choice to a greater extent. The packaging that customers pay attention to is not an image or a fancy, but whether the packaging can convey people's emotions, resonate with people, and reflect the level and lifestyle of the target group.

Finally, the packaging plan should match the characteristics of the product. This is actually the most basic point. Food packaging boxes should give people a sense of food rather looks like pharmaceutical. Or package men products similar to those for female.

------------------------

Innove is a leading custom cardboard gift boxes supplier from China, offering various fancy setup gift box packaging products and custom box designs service. The product lines include personalized odd shaped boxes, round boxes, square boxes, rectangular boxes, telescoping boxes, shoulder boxes, cardboard drawer boxes, collapsible gift boxes - for clothing packaging, hexagon explosion gift boxes, cardboard window boxes, nesting gift boxes sets -stacking, etc. We've been serving diversified industries like gourmet cookie gift boxes, flat desserts boxes, cardboard flower gift boxes, jewelry gift boxes, luxury apparel boxes, t-shirt packaging boxes with clear lids, etc.

How to make real GREEN packaging boxes for tea products

With the growing environmental awareness amid consumers, today's environmentally friendly green packaging has become a global trend. Innove Packaging believes that the concept of green packaging can mainly be interpreted in two aspects: protecting the environment and saving resources. The two are complementary and indispensable. But how can we achieve true "green packaging"?

1. Green Materials. The packaging materials should be non-toxic and harmless to the human body and living things. It should be noted that the package should not contain toxic elements.

2. Packaging Minimization. That is, in the packaging design, the designers should keep environmental protection and reducing waste in mind, as well as satisfying the basic packaging purpose.

3. Degradation of Packaging Waste. Make sure that the discarded packaging material can be decomposed in the natural environment without polluting the natural environment.

Innove Packaging is a professional high-end custom packaging boxes manufacturer. Go Green is our constant pursuit of packaging. Environmental protection and a green earth is what we're always working hard to achieve, together with every party involved!

1. Green Materials. The packaging materials should be non-toxic and harmless to the human body and living things. It should be noted that the package should not contain toxic elements.

2. Packaging Minimization. That is, in the packaging design, the designers should keep environmental protection and reducing waste in mind, as well as satisfying the basic packaging purpose.

3. Degradation of Packaging Waste. Make sure that the discarded packaging material can be decomposed in the natural environment without polluting the natural environment.

Innove Packaging is a professional high-end custom packaging boxes manufacturer. Go Green is our constant pursuit of packaging. Environmental protection and a green earth is what we're always working hard to achieve, together with every party involved!

Sunday, July 7, 2019

What are the difficulties with personalized, small-lot custom packaging demand?

In the historic

context of new retail era, brand developers and third-party platforms have

spared no effort in situational demand satisfaction, bringing new markets and

new business opportunities for personalized packaging.

After the rise of printing e-commerce,

new concepts such as personalized customization, small-volume customization,

and large-scale personalized customization have gradually emerged. In recent

years, the trend of small batches, individualization and customization in the

domestic consumer market has intensified, from Weiquan’s Word Game Bottles

campaign(“拼字瓶”) to the Colgate's Dare to Love series, and even to Oreo’s

custom packaging for Tmall platform.

Behind the personalized economy,

people's new lifestyles and new social concepts are gradually taking shape.

Throughout all the consumer trends and desires, many forms of personalization services

already come to being, personalized education, personalized travel services,

personalized wedding services, personalized gift customization, personalized

clothing customization, personalized luxury ordering... Printing-related

personalized applications are endless, and they are constantly evolving with

rapid growth. Human society has now entered a personalized era. With the

Internet technology, consumption upgrades and social development, this trend of

personalized development will become more apparent.

Back to the personalization

process of the printing industry, it is not easy to get started. And even

today, there is no mature profit model existing. The early players are mostly

in the industry. They have been struggling in the dilemma of where the traffic

comes from and how the customer cost is reduced. It doesn't seem to be as

smooth as I imagined.

The problem of personalized

customization is not a new topic, and it’s a problem that the industry has always

been working on: high service costs and high manufacturing costs. The most

tricky part lie with personalized customization is the contradiction between critical

requirements and small order quantity, low efficiency in winning orders; too

low output results in high factory cost of service and manufacturing and thus

low profit, which makes the factory unwilling to take orders.

There are two fundamental reasons

for the difficulty of personalization. One is that the order is inefficient and

the output is low compared to the big order. The second is that the factory

assembly line are designed for mass order production, which is not suitable for

small orders.

Therefore, personalized

customization must use a production mode suitable for small orders, do not shoot

mosquitoes with a cannon, in order to get out of the misunderstanding of

personalized customization.

The essence of the problem of

custom box designs is profit. If the profit brought by personalization is far

higher than the cost of fulfilling the order, this will become a profitable

thing, the problems with personalization will no more exist.

All in all, personalized

packaging is a tempting business, on the one hand, it is really profitable, and

the imagination is huge. On the other hand, we have also seen some of many

printing and packaging companies peers who have tried get the fruit failed in

practice.

Friday, July 5, 2019

Why choose cardboard boxes with foam inserts?

In many cases, cardboard boxes alone are not enough for packaging gifts or products. Some kind of inserts are then required, plastic blisters, cardboard trays, foam inserts, sponge and so on.

Foam inserts, as one of the mostly used, enjoy some advantages:

(1) Elasticity is an important characteristic of foam, which protects the product from shock and help survive rough handling in transit.

(2) Foam elasticity also enable it to better secure the product in place compared to other support material.

(3) Integral foam inserts of the same thickness with the product can be used, instead of piecing together.(However, if the ordering quantity is not too big, the foam inserts will usually be pieced together to save cost.) With computer process control, foam inserts are precisely cut to fit closely to the unique shape of the product, aperture size, varied depths, etc. Thus slots can be as small as 1.5 mm in width, and depth ranges from 0.5 mm, to 120 mm. Such precisely custom shaped foam inserts, with neat and smooth cuts, are perfectly integrated with the outer cardboard box and inner product.

Of course, coin has two sides, and foam inserts are not without blame. They are a little costly and not so green.

With all the things said, cardboard gift boxes with foam inserts are a premium choice for luxury packaging solutions, especially when it comes to bottle or other care-needed products.

Foam inserts, as one of the mostly used, enjoy some advantages:

(1) Elasticity is an important characteristic of foam, which protects the product from shock and help survive rough handling in transit.

(2) Foam elasticity also enable it to better secure the product in place compared to other support material.

(3) Integral foam inserts of the same thickness with the product can be used, instead of piecing together.(However, if the ordering quantity is not too big, the foam inserts will usually be pieced together to save cost.) With computer process control, foam inserts are precisely cut to fit closely to the unique shape of the product, aperture size, varied depths, etc. Thus slots can be as small as 1.5 mm in width, and depth ranges from 0.5 mm, to 120 mm. Such precisely custom shaped foam inserts, with neat and smooth cuts, are perfectly integrated with the outer cardboard box and inner product.

Of course, coin has two sides, and foam inserts are not without blame. They are a little costly and not so green.

With all the things said, cardboard gift boxes with foam inserts are a premium choice for luxury packaging solutions, especially when it comes to bottle or other care-needed products.

Sunday, March 3, 2019

Why are cardboard gift boxes the most suitable packaging for camellia oil?

With the growing awareness of healthy diet, green products have gradually

caught consumers’ eyeballs. Camellia oil is a type of cooking oil drawn from seeds

of camellia. Its production process can be divided into:

shelling, drying, crushing, steaming, oil extraction and filtration. Every step is a physical method. It is a true pure natural green edible

oil.

Camellia oil is a totally new oil category and is mainly produced in mountainous

rural areas. It has always been regarded as a royal tribute from the mountains.

It is known as the "oil king" and is superior to olive oil in

nutritional value.

Camellia oil allegedly has effects of anti-aging, hair conditioning, emollient

and Anti-microbial, etc. Camellia

oil also has the nickname of "longevity oil" and is especially

suitable for middle- and old-aged people.

Despite all the benefits of camellia oil, not many people know about it. How

could that be?

A good product entails a good packaging, not necessarily expensive, but

the packaging represents the immediate image of the product inside and the brand

behind. Therefore, not only should the packaging appeal to the consumer visually, but also

help convey the merits of the product and the brand. Camellia oil, as a new

thing to the general public, requires a proper and selling packaging.

Cardboard gift boxes packaging, compared with other materials, has

distinguished advantages. To name a few, cardboard gift boxes are more

convenient, affordable, and environmentally friendly than wooden or plastic boxes.

How to Select Cardboard Gift Boxes Supplier?

How can you select your cardboard gift boxes supplier? We, at Innove Packaging, believe that an important

dimension is the quality of their products (cardboard gift boxes) . We can determine the

gift boxes’ quality from these aspects:

1. Smoothness.

The surface smoothness for general-purpose gift boxes must be kept within +/-

1mm. This is the minimum requirements to make sure they look good. And this

also, to some degree, represents a gift boxes factory’s level of workmanship

and quality control.

2. Color.

Color can make or break the custom printed gift packaging. If you see gift boxes

with distinct color discrepancy, and you can just cross the maker off your

vendor list. A purpose of gift boxes packaging is to add a touch of aesthetic

and luxury. If a factory fail to realize the desired color effect, chances are it’s a poorly organized company!

3. Brightness and viewing angle.

The

brightness and viewing angle of the appearance of the paper can also be checked.

From every direction, the cardboard gift boxes should be bright and gives a high-end look.

4. Safety.

Safety is also critical for cardboard gift boxes, especially

when it comes to the packaging of food and tea boxes etc.

For all the emphasis on quality, there are many other factors that can be taken into account, such as pre-sales & after sales support, designs,response time and supply ability, etc.

Sunday, February 3, 2019

High Stakes in Food Packaging Requires Right Ink for Printing

When ink is applied to food packaging as a printing material, it must be non-transferable. Prints in food packaging should not use conventional inks. The printing company must ensure that all the solvents in the ink are completely volatilized after printing. The ink needs thorough curing and meet the corresponding industry standards.

::Phasing out of Hazardous Benzene-solvent Inks::

In current printing for plastic food packaging, benzene-soluble chlorinated polypropylene inks are the most widely used, both the manufacture and use of which are in good practice. Such inks are mainly used in the printing of BOPP (biaxially oriented polypropylene) materials, and through gravure. Despite the benefits of good printing suitability & post-press processing performance and fast drying, they also have as big disadvantages. Firstly, the solvent residual in prints from such inks is high and toluene is toxic. Secondly, as the thermal stability of the chlorinated polypropylene is poor, the solvents tend to release chlorine to form hydrogen chloride during the production and storage, which makes the ink more acidic, causing severe corrosion to the printing plate roller. Also, the benzene-soluble ink can destroy the ozone layer and cause harm to workers' health and safety during use. And the residue remaining in the packaged product will cause a certain degree of contamination of the food in the package. This type of inks are phasing out, and regulations for prohibiting or controlling the use of this ink have already been developed in Europe and some other countries.

Because of the problems of benzene-soluble inks, environmentally friendly inks came into being. The use of environmentally-friendly inks does not pollute the environment, nor cause physical harm to the operator, nor incur contamination to the contents.

::Phasing out of Hazardous Benzene-solvent Inks::

In current printing for plastic food packaging, benzene-soluble chlorinated polypropylene inks are the most widely used, both the manufacture and use of which are in good practice. Such inks are mainly used in the printing of BOPP (biaxially oriented polypropylene) materials, and through gravure. Despite the benefits of good printing suitability & post-press processing performance and fast drying, they also have as big disadvantages. Firstly, the solvent residual in prints from such inks is high and toluene is toxic. Secondly, as the thermal stability of the chlorinated polypropylene is poor, the solvents tend to release chlorine to form hydrogen chloride during the production and storage, which makes the ink more acidic, causing severe corrosion to the printing plate roller. Also, the benzene-soluble ink can destroy the ozone layer and cause harm to workers' health and safety during use. And the residue remaining in the packaged product will cause a certain degree of contamination of the food in the package. This type of inks are phasing out, and regulations for prohibiting or controlling the use of this ink have already been developed in Europe and some other countries.

Because of the problems of benzene-soluble inks, environmentally friendly inks came into being. The use of environmentally-friendly inks does not pollute the environment, nor cause physical harm to the operator, nor incur contamination to the contents.

Friday, February 1, 2019

How to Design Cosmetic Cardboard Gift Boxes

Clothes

make the man, that’s also true to products, especially vanity products like cosmetics.

Somehow, packaging is vital to commercial success of cosmetics. Humans are visual

"animals", we all like beautiful things. Furthermore, if a product does not make any change in packaging for years, then we have good reason to doubt the

cosmetics brand. Of course, gift packaging styles vary largely in different

target markets. There’s not a single standard that fits everywhere. Below are some opinions based on China markets only.

Therefore, the pattern of the cosmetic packaging boxes must be clear, soft, elegant and

beautiful. Don't stuff too many pictures, otherwise it will not highlight the

key messages you want to convey. And the color matching of the box is very

important, for example, most women like white, red and pink, which are called

women's colors, women's products packaged in such color boxes may easily appeal

to them. However, most men seem to like serious & solemn black, therefore, black

is also called men’s color. Thus men's commodities packaged in black can be

favored by men.

Cosmetic color box packaging should accurately convey product information, as well as

the shape, color, and pattern used in packaging. Do not violate people's normal

habits. After all, the good feeling comes directly from the feeling of the

shape, color, pattern and material of the package.

The most important thing is the box design of the cosmetic color packaging box. They

can be specially designed according to the shape and size of the cosmetics. Different

packaging materials, shapes and patterns are employed based on the cosmetics classification

of being high-end of mid-grade. The packaging position of class goes a long way

in cosmetics brand image and sales.

Innove supplies various cardboard gift boxes for cosmetic packaging: custom round fragrance gift boxes, rose gold round skincare boxes with telescopic lids, handmade personalized perfume gift boxes, hexagonal shaped explosion boxes, eye primer small cosmetic boxes, small makeup brush gift packaging tubes, skincare packaging boxes with clear lids, bulk lip balm containers and kraft paper push-up lipstick containers etc..

What is spot color printing in cardboard gift boxes?

Spot color printing(专色印刷) is a printing process

involved in offset printing, using a spot color ink (pure or mixed)

specifically formulated according Pantone code. It’s a single and extra run

other than the general CMYK 4C printing process, and thus requires its own

lithographic film.

Then on what occasions is spot color printing necessary? (1) When the cardboard gift boxes designs involve gold or silver color. Golden and silvery colors differs greatly from rest colors and are extremely opaque. Thus they are impossible to realize on the print by regular CMYK offset printing process. In this case, spot color printing can be used to achieve golden or silvery tones (An alternative method to foil stamping).

(2)The prints often comprise uniform color areas of varying gradient colors and text. These color areas and texts can be achieved either by the process of registering in offset printing or by spot color printing. With comprehensive trade-off between improving print quality and saving the runs of registering, it is sometimes necessary to use spot color printing (An alternative method to registering).

Spot color printing uses a non-standard offset ink such as metallic, fluorescent, or hand-mixed ink. Every color needs one lithographic film and an extra printing run. Also, the potential for problems will generally increase. All these will be factored into the total cost of the final gift boxes.

[Innove Packaging designs and manufactures window gift boxes, rigid shoulder boxes, decorative drawer gift boxes, hexagon explosion cardboard boxes, luxury nesting apparel gift boxes of 3, and custom odd shaped boxes, etc.]

Then on what occasions is spot color printing necessary? (1) When the cardboard gift boxes designs involve gold or silver color. Golden and silvery colors differs greatly from rest colors and are extremely opaque. Thus they are impossible to realize on the print by regular CMYK offset printing process. In this case, spot color printing can be used to achieve golden or silvery tones (An alternative method to foil stamping).

(2)The prints often comprise uniform color areas of varying gradient colors and text. These color areas and texts can be achieved either by the process of registering in offset printing or by spot color printing. With comprehensive trade-off between improving print quality and saving the runs of registering, it is sometimes necessary to use spot color printing (An alternative method to registering).

Spot color printing uses a non-standard offset ink such as metallic, fluorescent, or hand-mixed ink. Every color needs one lithographic film and an extra printing run. Also, the potential for problems will generally increase. All these will be factored into the total cost of the final gift boxes.

[Innove Packaging designs and manufactures window gift boxes, rigid shoulder boxes, decorative drawer gift boxes, hexagon explosion cardboard boxes, luxury nesting apparel gift boxes of 3, and custom odd shaped boxes, etc.]

Tuesday, January 22, 2019

Restructuring in China Packaging Industry: Green Packaging Develops as a Growing Trend

Recently, “Quality Month” campaigns have been carried out in

some provinces in China. Local quality supervision departments have conducted spot

checks on retail packaging for food, beverages, alcohol, tea, cigarettes,medicines, health products, cosmetics and other commodities that are selling

well. According to industry insiders, with the increasing environmental

awareness, green packaging has become a trend. The market for pollutional materials

keep shrinking, while packaging and printing companies accelerated their

transformation, making product packaging gradually move toward green & environment

friendly.

Since the introduction of new “Packaging Regulations” in China, the packaging industry has undergone continuous deep restructuring. Some data show that about 55% of packaging related companies realize that a positive environmental image is very important for their future development; 70% of companies believe that consumer demand, value and recyclable signs on the packaging are important in their marketing activities. Compared with developed countries, China's current color gift box packaging market is far from maturing. While there’s no specific definition for cardboard gift box packaging yet, companies have no accurate understanding of the scope of color it.

A company executive said, the essence of their newly introduced printing platform is to, help accurately understand the scope of cardboardgift box packaging segment the packaging markets, grow a strong brand. While at the same time, the environmental protection measures will be put into practice, using high-quality green materials and advanced pollution-free printing technology.

According to industry insiders, cardboard gift boxpackaging, as an environmentally friendly, cost-effective and mature packaging form, has an infinite development prospect. And with the rapid consumption growth boosted by China’s sustained economic growth, environment-friendly packaging will have a bright future.

Since the introduction of new “Packaging Regulations” in China, the packaging industry has undergone continuous deep restructuring. Some data show that about 55% of packaging related companies realize that a positive environmental image is very important for their future development; 70% of companies believe that consumer demand, value and recyclable signs on the packaging are important in their marketing activities. Compared with developed countries, China's current color gift box packaging market is far from maturing. While there’s no specific definition for cardboard gift box packaging yet, companies have no accurate understanding of the scope of color it.

A company executive said, the essence of their newly introduced printing platform is to, help accurately understand the scope of cardboardgift box packaging segment the packaging markets, grow a strong brand. While at the same time, the environmental protection measures will be put into practice, using high-quality green materials and advanced pollution-free printing technology.

According to industry insiders, cardboard gift boxpackaging, as an environmentally friendly, cost-effective and mature packaging form, has an infinite development prospect. And with the rapid consumption growth boosted by China’s sustained economic growth, environment-friendly packaging will have a bright future.

What is green packaging?

Green Packaging means pollution-free or Environmental Friendly Packaging, which refers to packaging that is harmless to the ecological environment and human health, can be reused and regenerated, and is in line with sustainable development. This concept contains two implications: one is to protect the environment, and the other to conserve resources.

Innove is a leading custom cardboard gift boxes supplier from China, offering various fancy setup gift box packaging products and custom box designs service. The product lines include personalized odd shaped boxes, round boxes, square boxes, rectangular boxes, telescoping boxes, shoulder boxes, cardboard drawer boxes, collapsible gift boxes, explosion gift boxes, cardboard window boxes, nesting gift boxes sets, etc.

Innove is a leading custom cardboard gift boxes supplier from China, offering various fancy setup gift box packaging products and custom box designs service. The product lines include personalized odd shaped boxes, round boxes, square boxes, rectangular boxes, telescoping boxes, shoulder boxes, cardboard drawer boxes, collapsible gift boxes, explosion gift boxes, cardboard window boxes, nesting gift boxes sets, etc.

Sunday, January 20, 2019

How to Design Gift Packaging that Appeals to Consumers

Generally, custom designs of gift packaging has direct impact on the

sales of the contained products. For packaging like Mid-Autumn moon cake boxes,

tea gift packaging boxes, cosmetic boxes, etc., consumers' first impressions would

often determine their buying decision. So how can we design an attractive and

selling gift box packaging? Listed below are some takeaways for good custom

gift boxes designs:

1. Color:

Color has a great impact on people's emotions. Therefore, we believe that the

color of the wrapping paper can be distinguished by age and gender of target

market segmentation: men should be mainly in cool colors, women can go bright

colors or simple but elegant color, children should

choose bright & colorful colors, and lovely patterns with corrugated cardboard.

2. Theme: This is the basis for determining

gift box packaging. Gifts are available in a variety of themes. For example,

love gift packaging can take heart shape or rose pattern, decorated with Cupid's arrow, showing a deep

affection. The family gifts can be decorated with warm colors to highlight the

intimacy of simplicity and tranquility.

3. Artistic: Each carefully processed

& packaged goods can reflect a certain artistic. The role of small embellishments like

decorative strips and ornament

flowers, etc. should be paid attention to. They may increase the artistic

effect to the finishing touch of gift packaging.

Design & Printing on Corrugated Paper Gift Boxes

1. Strength: The flute design

is the primary content of the strength. The corrugated cardboard includes

single-flute and multiple-flute layers. And for each flute layer, there are 3

varying profiles to be chosen from: flute A, B & C. Multiple-flute boxes

usually come in mixing flute profiles. Designers must choose the right flute

type and profiles according to the pre-design knowledge.

2. Material selection: the choice of cardboard material is

an important part of the strength design, it not only affects the printing

effect, but also has a bearing on the physical properties of the finished

corrugated boxes. For example, there is a close relationship between the water

content of the paper and the strength of the carton. While choosing paper to

use, different weather conditions must be considered. And paperboard produced

must also meet the requirements in terms of physical properties such as

breakage resistance, side pressure and adhesion.

An important reason for the popularity of cardboard packaging is their environmental benefits. Thus the use of consumables like ink,

additives, polishes, and the recycling properties of paperboard itself must be

in compliance with environmental requirements. And when used for packaging food, medicine or children's toys, the cardboard boxes must also meet the

requirements of hygiene, health and safety. Of course, in case of export, it is

necessary to consider the relevant laws and regulations of the destination

country.

3. Size: In designing the box size, in addition to the

reasonable length, width and height ratio according to the contents, designers

should also consider the right container types to make full use of packaging

space.

4. Printing process problems: designers need to pay

attention to the difference between various printing processes. The printing

methods commonly used in corrugated boxes in China mainly include offset

printing, silkscreen printing, flexo printing, and gravure printing etc.

Changes in printing methods directly affect other processes, and even result in

change of print materials. For example, it’s difficult to use water-based ink flexographic printing over coated

paper. When using the popular flexo printing

process, it is necessary to pay attention to the layout.

With flexo printing, thin lines, small texts, and patterns

with dots should not be arranged on a layout with a large-area flush color

background. Because the full-page flush color background printing requires a

larger printing pressure, it is easy to make small text and pattern

deformation, causes printing problems like blurring, broken lines, missing font

strokes, and dot loss, etc. and will result

in premature wearing or damage of the printing plate. If they had to be in the

same page, then the exposure time should be extended to improve the hardness

and printing durability of the plate at the fine image.

In order to overcome the unevenness and roughness of the

cardboard surface, the printing plate is required to be wear-resistant, strong

in impact resistance, moderate in hardness, good in resilience after being

pressed, uniform in ink and thickness. Based on the pattern, the size of the

text, lines and the material of the corrugated board, change the layout, hardness

and making methods of the flexo plates accordingly. When the corrugated board

is of poor quality or with full page background printing, thicker and softer

flexo plate should be used. When the corrugated board has good quality or printing

fine patterns and small characters, choose harder and thinner or resin flexo

plates.

If the printing surface of the corrugated board is uneven,

rough, warping and with other problems, it may cause filling in(糊版), crush, wearing or damage to the flexographic resin

plate. Therefore, the quality of the base paper should be strictly controlled in the printing process of cardboard gift boxes.

Custom Designs of Cardboard Gift Box Packaging

Modeling and structural design are an important part of

commodity packaging. Packaging designers must ensure that the box structure has

sufficient strength, hardness and resistance to environments. There are two things

to be addressed: firstly, the primary function is to protect the products, and secondly,

it should meet the important characteristics of modern packaging, such as

transportation and processing etc.

Qualified cardboard gift boxes start with the right structural design.

Designers must not only truly understand the customer's intentions, but also be

familiar with the subsequent processing techniques. Only in this way can the

customer's intention be converted into a qualified packaging, and the

subsequent processing of the product can be smoothly carried out. Before the

design begins, the designer should understand the nature, shape, size and weight of the contents; the arrangement of

the contents, the transportation method, the stacking method; the storage

environment, the transportation route and time, and the box type and materials.

Once the needed information as mentioned above has been

determined, it is also important to know whether the desired box is transport-oriented

or sales-oriented. Sales-oriented paper gift boxes fall into the category of

commercial packaging, and focus on the appearance of the boxes, and printing needs

to be considered. Transportation-oriented boxes are industrial packaging. It is

necessary to consider the requirements of compression and shock resistance. Thus,

designers must determine the position of the opening and die cutting without

affecting the strength. In case of reusability, they also need to consider the

efficiency of packing and operation.

Subscribe to:

Comments (Atom)